5.7 Record the Goods Issue vs. the Delivery

| Record the Goods Issue vs. the Delivery | |

| Performer: | Logistics |

| Role: | Logistics Assistant |

| Transaction : | WingsII – VL02N |

Record Good Issue

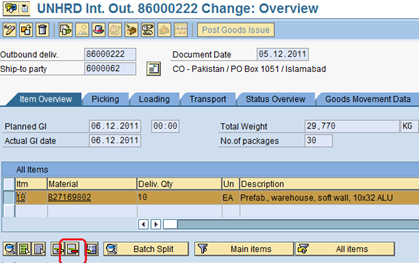

When cargo leaves HRD warehouses the Good Issue has to be posted in the system by 24 hours from the departure of the cargo from UNHRD or Supplier's warehouses. To post the Good Issue go to ‘Change Outbound Delivery’ thru transaction VL02N or follow the path below:

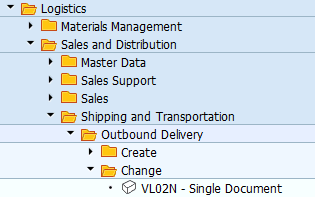

Logistics > Sales and Distribution > Sales and distribution > Shipping and transportation > Outbound Delivery > Change

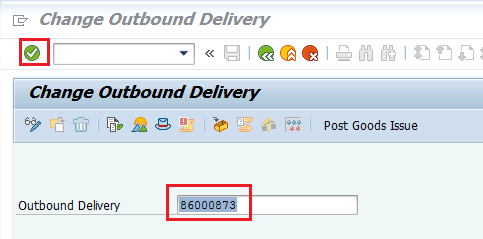

Enter the Outbound Delivery number and click on ![]() :

:

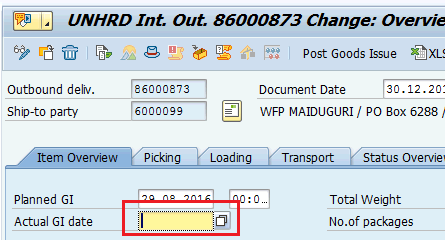

Enter the actual date of departure in the Actual GI date field; in case the field is already populated overwrite the date:

NOTE: Good Issue can be posted by applying the actual date of departure within the valid Financial period (i.e. by the 5th of each month).

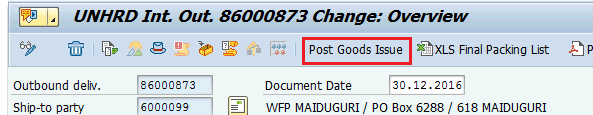

Click on ![]() and click on

and click on ![]() to save:

to save:

You will receive a confirmation that the Outbound Delivery document has been saved:

NOTE The Good Issue number generated from the Outbound Deliveries follows the 013* range and does not have any Warehouse Management and Financial impact.

Reverse Good Issue

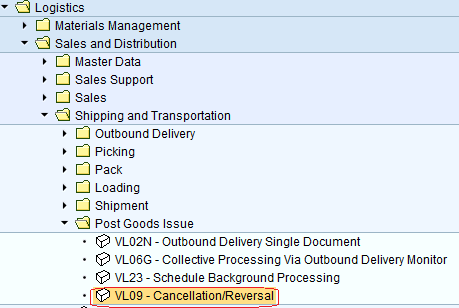

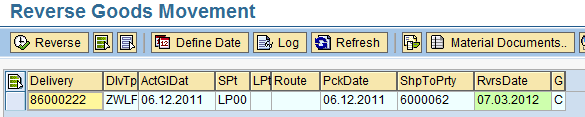

In some circumstances, it might be required to cancel the Good Issue posted (e.g. in case of change of cargo composition or in case the Partner opts out the sales process at Delivery stage). To reverse a Good Issue against Outbound Delivery, go to Transaction VL09 or enter the path below:

'Logistics > Sales and Distribution> Shipping and Transportation > Post Goods Issue'

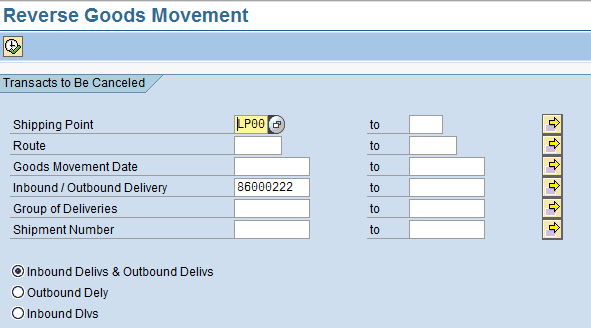

Insert the following data:

- LP00 as shipping point

- Enter the GI date in the 'Goods Movement Date' field (NOTE it must be the same date entered at the time the GI has been posted).

- Enter the OD number related to the GI that is required to be reversed

- Click on 'Execute'

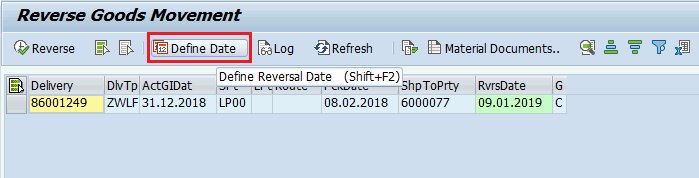

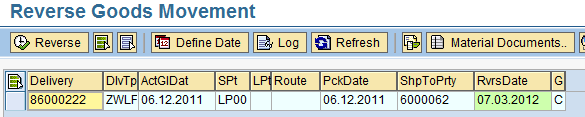

Select the delivery prompted by the system by highlighting it and click on click on ![]() to enter the actual date of departure (i.e. the same date listed in the Actual GI date column):

to enter the actual date of departure (i.e. the same date listed in the Actual GI date column):

NOTE In case the Actual date of GI falls in a financial period that is closed at the time of the reversal, the earlier date possible must be applied as Reversal Date

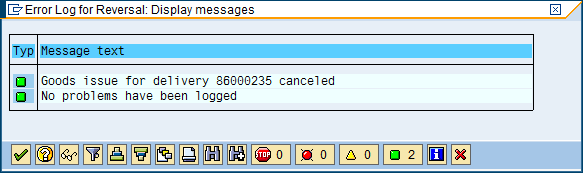

The system will prompt with the msg below:

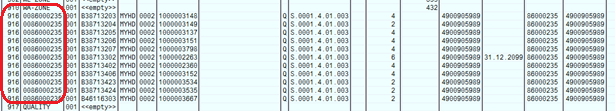

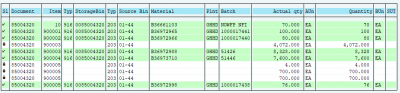

All the materials contained in the outbound delivery are then back in the 916 storage type (shipping area) as at this stage the GI reversal is completed, but materials are still committed in the outbound delivery:

Return items to stock and empty Outbound Delivery

The system does not allow the return of part of the materials committed in the outbound delivery; so in case of partial GI reversal, it is required to move all the items on the OD back into stock and then re-populate the outbound delivery as required.

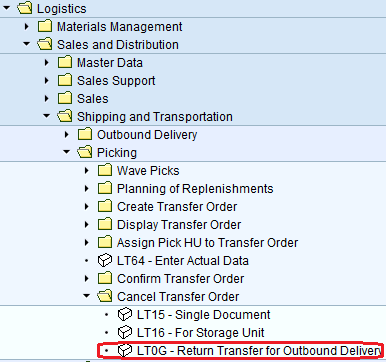

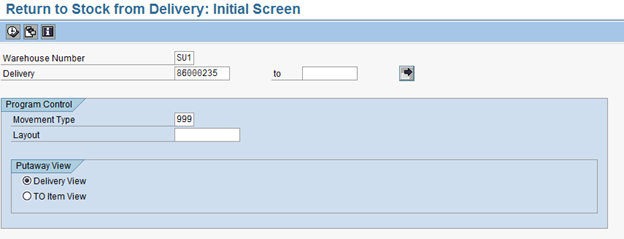

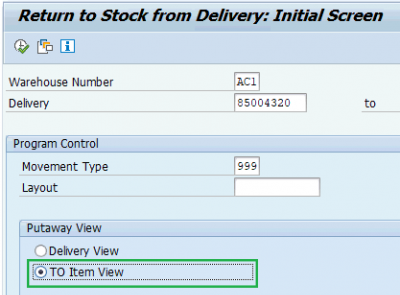

To completely return the material in stock, go to 'Return to Stock from Delivery: Initial Screen' by running transaction LT0G or following the path below:

'Logistics > Sales and Distribution > Shipping and Transportation > Picking > Cancel Transfer Order'

Enter the Warehouse number, the outbound delivery number and click on 'Execute' ![]()

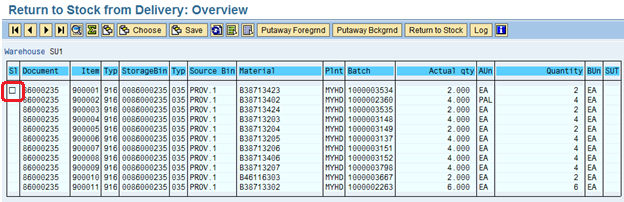

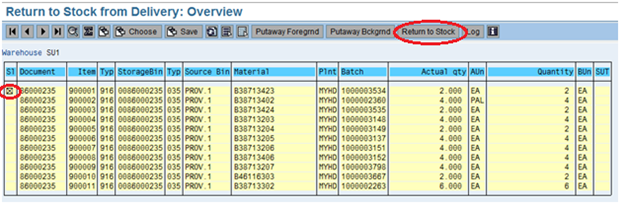

The system will list all the materials from the outbound delivery; select the box circled below under the SL column:

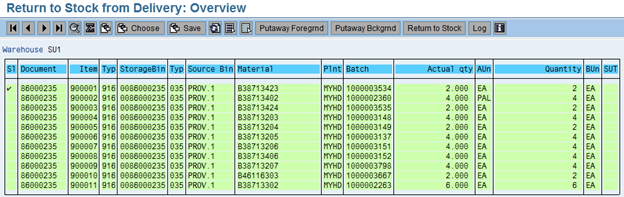

The system turns the table into green colour, meaning that the return to stock from delivery is already confirmed (TO is reversed):

All the items committed in the outbound delivery are now returned into original bin locations. To confirm the return of items into stock, go to transaction LT12 and confirm the TO created.

In case the system does not allow the return in stock the items the status bar into lightning bolt icon check the information available in the Log:

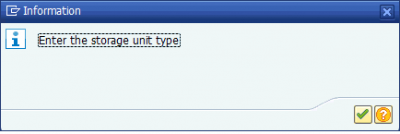

The Information box shows the reason why it is not possible to process the return to stock of all the items in the OD as a whole; the example below refers to the need for further information required to process the return of stock:

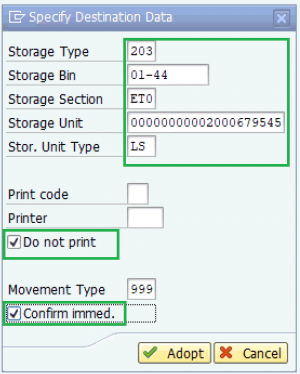

The reason for this scenario is that for Storage type configuration, "SUT Check" is marked as active. Hence when a returning to stock is required after cancelling the delivery, it is required to basically doing a "put away process" back into the bin. Because of "SUT check" is active, the user requires to enter the SUT type (e.g. LS, XL, MS…) so that the system can determine palletization quantity and automatically propose the number of bins to accommodate the stock to be returned back to the bins. To complete the return to stock system requires to allocate the number of bins required. Hence it blocks the user and requires to "Enter the Storage unit type".

To complete the return to stock start transaction Lt0G again and select "To Item View" option:

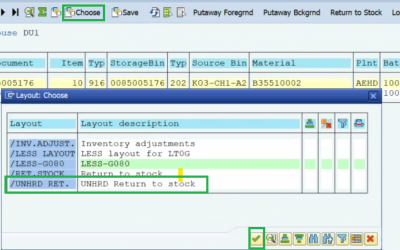

Click on "Choose" and select the Layout "UNHRD Storage":

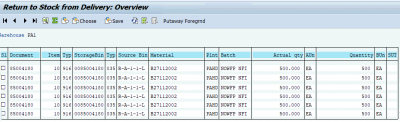

System allows the user to select each single line, which have to be processed one by one to complete the to return to stock of the the materials back to the bins of origin:

Select the lines one by one and select select “Putaway foreground” option:

Fill in below fields based on the information related to the picking process and click on "Adopt"; if required search for the Transfer Order generated by the picking process and display it thru transaction LT23:

The line status turns to green and next line has to be processed, if any, to complete the return to stock of all the items:

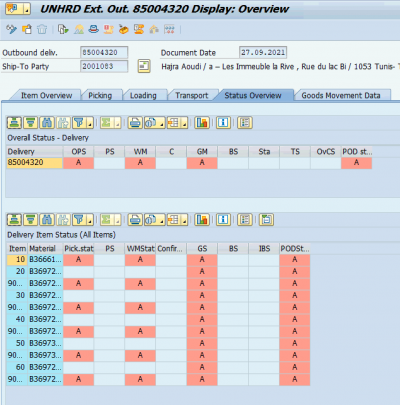

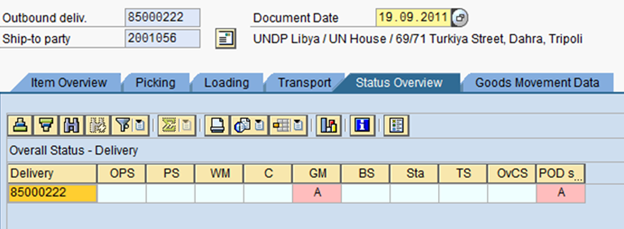

When completing the return to stock of items the OD status is turned to picked status A for "Not Yet Processed":

To be noted that when items are returned in stock from the despatching area, they anyhow remain listed in the outbound delivery, which has to be eventually modified to reflect new cargo composition vs customer’s requirements or cancelled in case the Partners opts out.

In case the Partner opts out, mark the SO as cancelled, as detailed in 3.13 Delete the Pro Forma Invoice. Delete the material lines from the delivery going to "Change Outbound Delivery" thru transaction VL02N, select all item lines and click on the icon ![]() .

To complete the process, click on

.

To complete the process, click on ![]() before to save the OD.

before to save the OD.

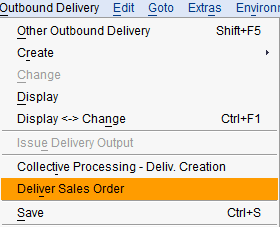

In case the Partner request to change cargo composition, the SO has to changed to reflect the changes required to be applied to the outbound delivery. Go to 'Change Sales Order' thru transaction VA02 and modify the materials codes and/or quantities, when partners request to change the cargo composition. Go to 'Change Outbound delivery' thru transaction VL02N, enter the delivery number and click on 'Outbound Delivery/Delivery Sales Order' to populate the outbound delivery in line with changes applied in the SO:

Proceed with standard process to complete the delivery and post the GI.

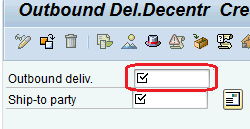

NOTE In case of total change of cargo composition, all lines from the Outbound Delivery have to be removed and the OD has to be deleted; to retain the first OD number, go to 'Change Sales Order' thru transaction VA02 to create a new Delivery and simply enter the old OD number in the Outbound deliv. box to retain it: the system will hold the same number without creating a new OD number:

Total cancellation of Outbound Delivery

if the items have to be “de-committed” from the OD and completely returned to stock (e.g. customer cancels its request), go to 'Change Outbound Delivery' thru transaction VL02N, select all the materials and delete them by clicking on the icon ![]() :

:

NOTE In case the 'Return to Stock from Delivery" thru transaction LT0G does not work, (the outbound delivery appears locked in the LT0G output screen) means that the user has wrongly locked the material by processing the TO against material not present in the warehouse. In this case, the "WM picking status" in the outbound delivery has to be reset from “C” to “A”. Starting from that "WM picking Status", the user is allowed to modify the outbound delivery. After having posted the GI reversal by 'Reversal Goods Movement' thru transaction VL09, go to 'Create Transfer Order' thru transaction LT10 to move back the stock from the dynamic bin under storage type 916 to the original bin. After this posting the "WM picking status" is still in "C" (completed):

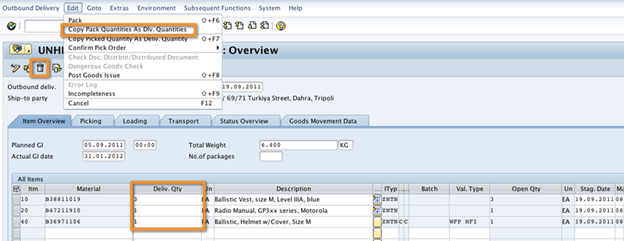

This is why the system doesn't allow emptying the outbound delivery and shows the standard error message “VL 173”. Go to 'Change Outbound Delivery' thru transaction VL02N to reset the "WM picking status" for the outbound delivery; copy the "Deliv. qty" of each item on and excel table (this might be useful for recovery reason, as you can see in case 2b below) and click on "Edit" and select "Copy Pack Quantities As Dlv. Quantities".

By following this process the system deletes the "deliv. qty" of each outbound delivery items and resets the "WM picking status" to "A”:

Outbound delivery is then ready to be processed either option 2a or 2b below:

- 2a. delete the outbound delivery thru standard process described above

- 2b. quantities saved for recovery purposes can be in the field "Deliv qty" and complete the outbound delivery thru picking and Good Issue posting .