11.4 Inbound flow monitor

| Putaway thru TRANSFER ORDER from GR | |

| Performer: | Warehouse staff |

| Role: | Warehouse roles |

| Transaction : | WingsII – ZSCR035, LB10 |

Performing monitoring of inbound flows is vital for maintaining operational efficiency, minimizing risks, controlling costs, and ensuring that supply chain activities are aligned with business goals. Inbound flow monitoring is crucial for several reasons:

Efficiency and Timeliness: it ensures that all units involved in the inbound flow are well organized to perform receipt of shipments on time and in the right quantity. This timely monitoring can prevent delays in supply chain processes, helping the organization maintain smooth operations.

Inventory Management: by closely tracking the inbound flow, businesses can have a clearer picture of their inventory levels. This allows for better planning, forecasting, and stock control, reducing the risk of overstocking or stockouts.

Error Detection: regular monitoring allows for the identification of discrepancies or issues early in the process, such as missing items or incorrect specifications applied in the PONFs and/or POWMs. Detecting these issues promptly helps to avoid costly mistakes later, such as delays or disruptions in production or customer service.

Cost Management: proper inbound monitoring helps optimize logistics costs. By identifying inefficiencies in the flow, such as unnecessary storage time or transportation delays, it can help reduce costs associated with warehousing, transportation, and labor.

Supplier Relationship Management: when inbound flows are consistently monitored, it becomes easier to spot recurring issues with suppliers. This data can be used to improve collaboration, resolve issues quickly, and negotiate better terms or improvements with suppliers.

Inbound flow monitoring can be performed by control incoming shipments and Warehouse Management actions to be performed upon receipt of the items:

Monitor open Purchase Orders

Monitoring of the WINGS Purchase Order (PO) transactions is an essential part of the procurement process. It is advised by Corporate that all Procurement Officers regularly monitor the current and past Purchase Orders in WINGS to ensure that they show consistency in the data, viz. the correct PO Type was used, the PO is fully released, PO’s have been ticked “delivery complete”, etc.

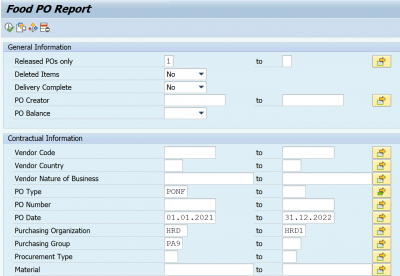

Monitoring of POs is performed to check balances still to be delivered or services that still have to be rendered, check that PO’s have been ticked “Delivery complete”, correct PO Type was used, etc. To perform this action, run customized transaction ZSCR035. This transaction can also be used for Statistics purposes. Enter below selection criteria:

• Delivery Complete: select "No"

• PO Type: insert the PO types required to be monitor (e.g. PONF, POS, PONW, PONS, POWM, POJS, POLO, POIT, POOL etc.) or eave the field empty to list any type of POs

• PO Date: select Date Period

• Purchasing Organisation: select HRD and/or HRD1 for both competitive tendering re specific or framework agreements, and PONWs and POSWs waiver direct contracting, issued by UNHRD Procurement teams

• Purchasing group: to limit the search to you own hub, enter the proper Purchasing group (e.g. PA9, GH9, MY9) or the Purchasing group of centralized Procurement units i.e. IT9 and AE9

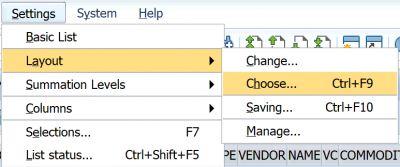

Once system shows the result, Click on Setting > Layout > Choose... to select the proper layout:

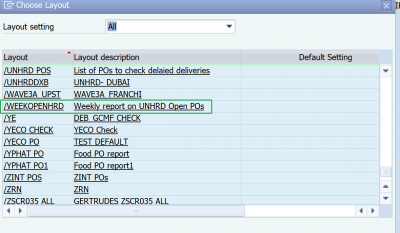

Select the layout "WEEKOPENHRD" to show the open POs:

The report lists the POs by showing under the column "QTY MTN" the quantities of items listed in the POs, in the next column it shows the unit and total value per line ("$/MT" and "VALUE US$" respectively). Following columns shows the quantity of items received in the system by GR posting and the balance ("GR QY" and "PO GR-BAL" respectively); same applies with Service Entry Sheets posted for Service POs and Transport POs:

In the very last columns the reports shows the related Purchase Requisitions, if any.

The report can be opened into Excel by clicking on the icon ![]() or exported on a local drive by clicking on the icon

or exported on a local drive by clicking on the icon ![]()

For further information on how to run this report, visit the document Monitoring Purchase Orders in WINGS available on WFPgo

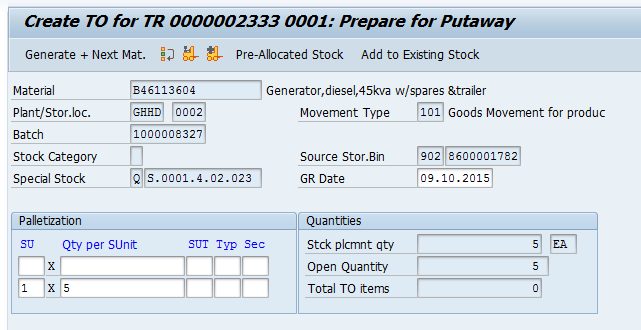

Putaway after posting of Good Receipt against PO for NFI and POWM

In case after the posting of GR against PONFs (with Q as account assignment) and POWMs, the system does not drive to the creation of transfer order directly, or in case the putaway action has to be performed on a later stage and/or by another staff member than the one performed the GR posting, follow the menu path described below or run transaction code LB10:

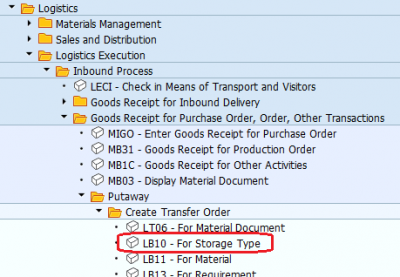

Logistics > Logistics Execution > Inbound Process > Goods Receipt for Purchase Order, Order, Other transaction > Putaway > Create Transfer Order > For Storage Type

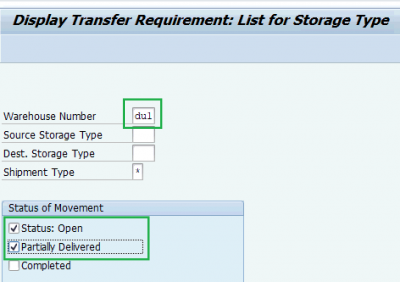

Insert the Warehouse Number, tick the box “Status: Open” and the box "Partially delivered" in the “Status of Movement” section and click on ![]() :

:

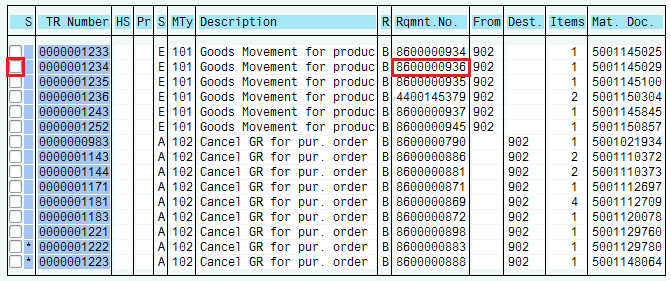

Choose the material document that we want to process by clicking on selection square:

NOTE: in case of multiple materials the system shows the screen below:

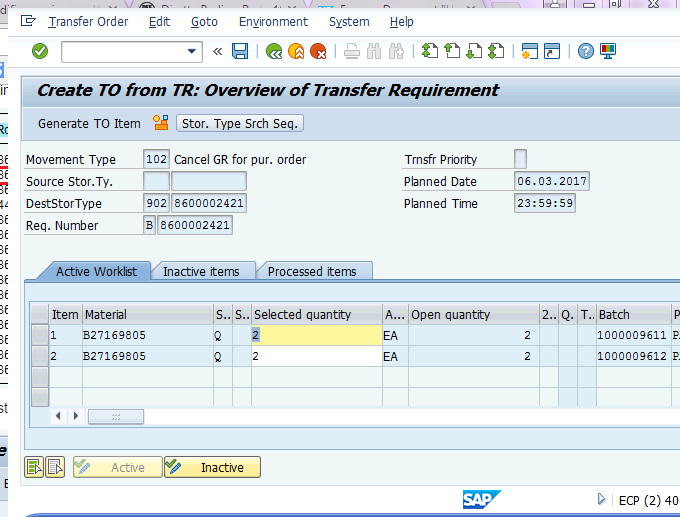

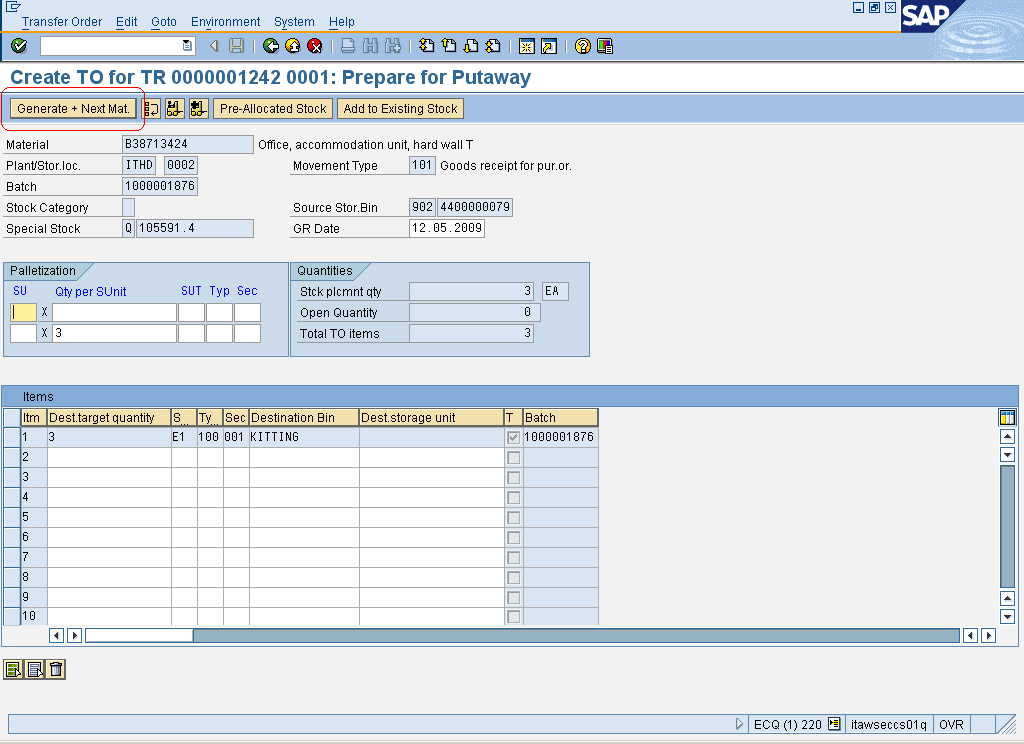

Click on ![]() tab and follow the steps to create a standard Transfer Order:

tab and follow the steps to create a standard Transfer Order:

Leave the palletization as proposed by the system and click on for ![]() for "Putaway in Foreground".

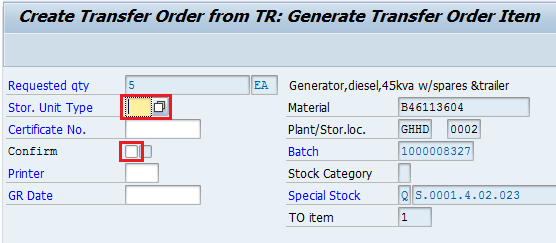

Select the proper Storage Unit Type and tick the Confirm box:

for "Putaway in Foreground".

Select the proper Storage Unit Type and tick the Confirm box:

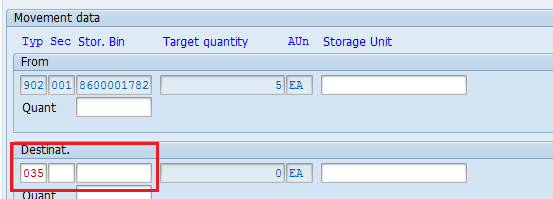

Fill in with the best Storage Type and Storage Bin. The system proposed the information starting from the putaway strategy recorded in the material master database for each material, if any; in case an alternative storage type and/or Storage Bin has to be selected, just enter the information in the Destination data and click on ![]() :

:

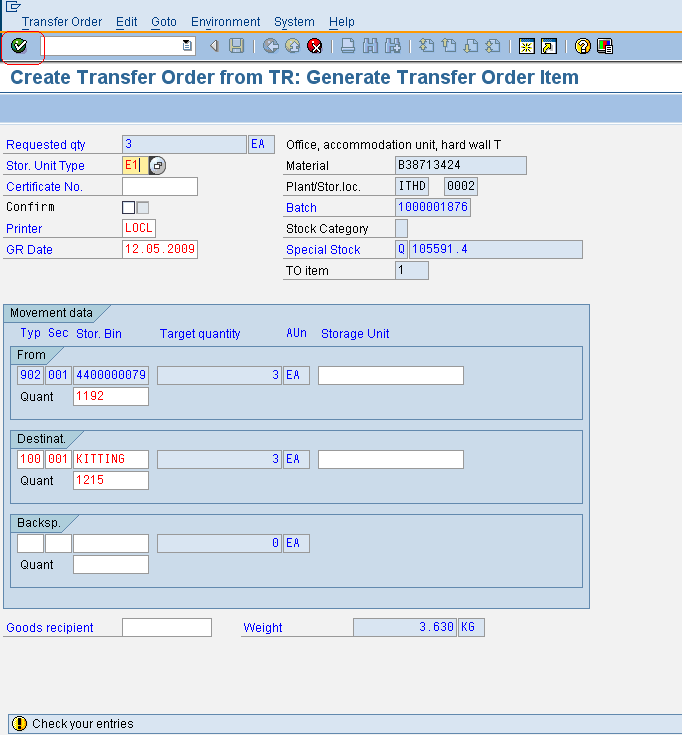

The system asks to check the information entered. Click again on ![]() as many times as needed:

as many times as needed:

Click on ![]() to continue with the next line item that requires to be processed:

to continue with the next line item that requires to be processed:

Click on ![]() as many times as needed.

as many times as needed.

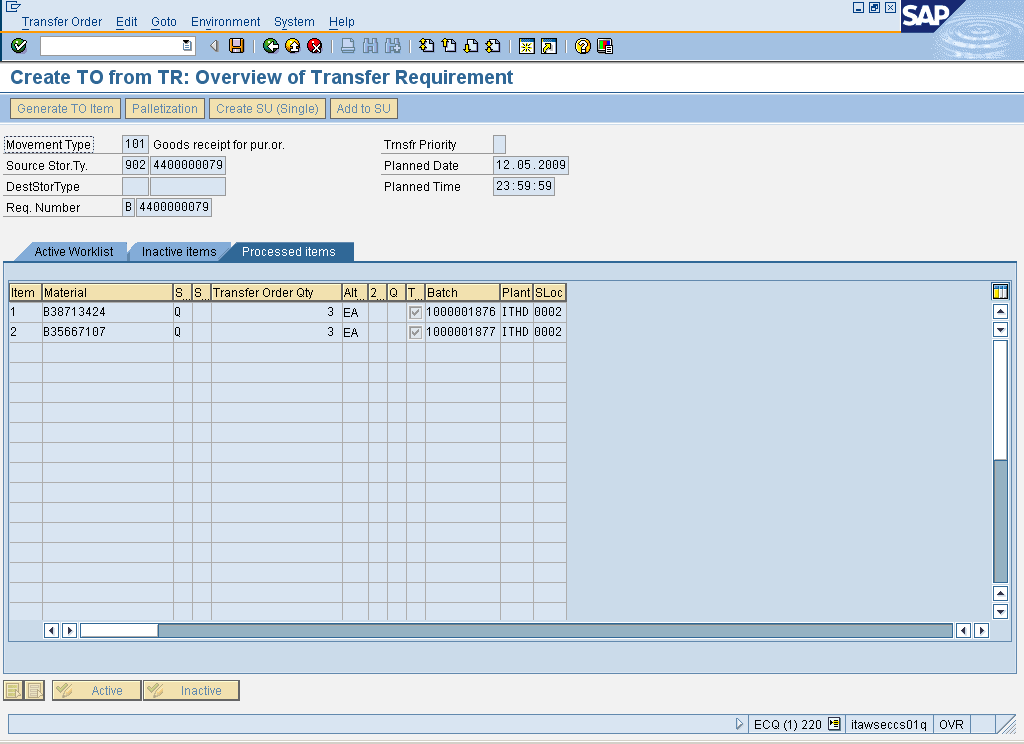

Select ![]() to make sure there are no more selectable items. If all the items of the GR have been processed the system displays the Overview for Transfer Requirement as fulfilled:

to make sure there are no more selectable items. If all the items of the GR have been processed the system displays the Overview for Transfer Requirement as fulfilled:

Click ![]() to save the Transfer Order.

to save the Transfer Order.

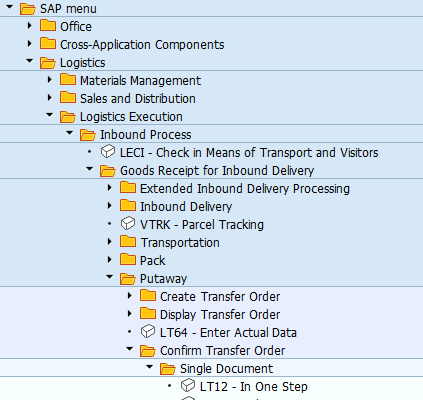

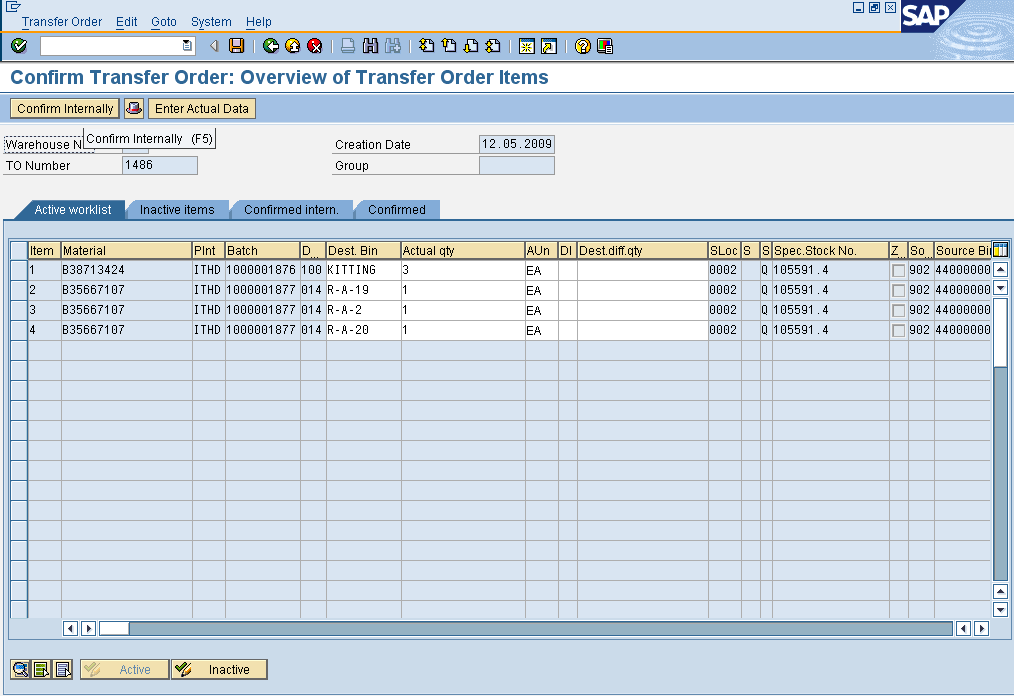

Confirmation of Transfer Order

If confirmation is not allowed before, or the user has not confirmed the putaway at the time of the TO creation, follow the menu path described below or run transaction code L712:

Logistics > Logistics Execution > Inbound Process > Goods Receipt for Inbound Delivery > Putaway > Confirm Transfer Order > Single Document

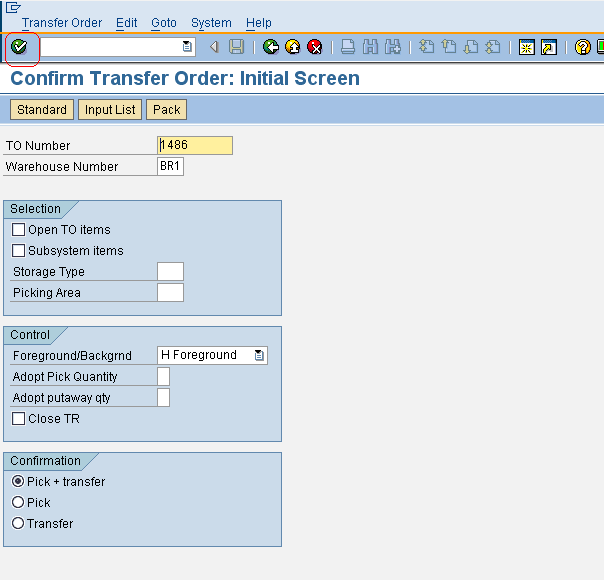

Insert the TO number that requires to be confirmed and click on ![]() :

:

The system displays all the items included in the TO: