5.4 Create Outbound Delivery

| Create Outbound Delivery | |

| Performer: | Logistics/Warehouse |

| Role: | Logistics Assistant/Storekeeper |

| Transaction : | WingsII – VL01N & VL02N |

Create Outbound Delivery

To create the Outbound delivery follow the path below:

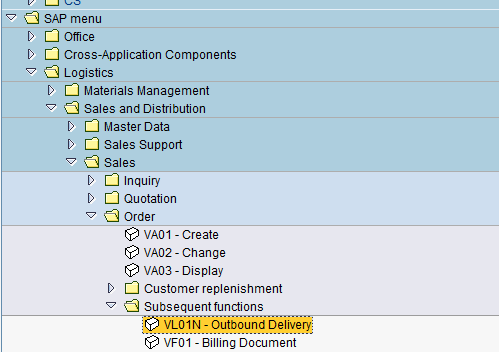

Logistics > Sales and Distribution > Sales > Order > Subsequent functions > Outbound Delivery

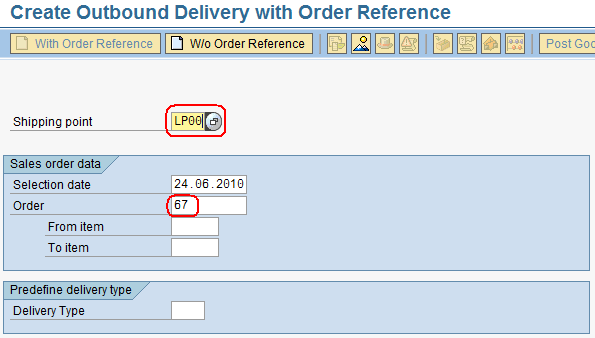

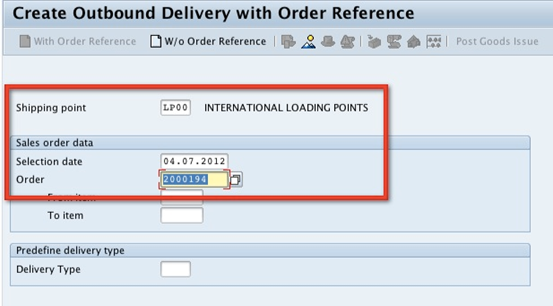

Enter the Sales Order from which the Outbound Delivery has to be generated, enter "LP00" for "International loading point" as Shipping Point. Depending on whether the goods are shipped all together or in partial shipments, select the lines of interest by by entering the line number in the fields 'From item' & 'To item. This can be useful in case of partial shipments. If no line selection is entered, the system picks up automatically all the material lines in the SO.

Click on enter ![]() :

:

The system derives all the material lines in the SO or the line items selected from it by copying these into the Outbound Delivery. Information on ship-to-party and means of transport are also derived into the SO automatically but can be changed on a later stage, if required.

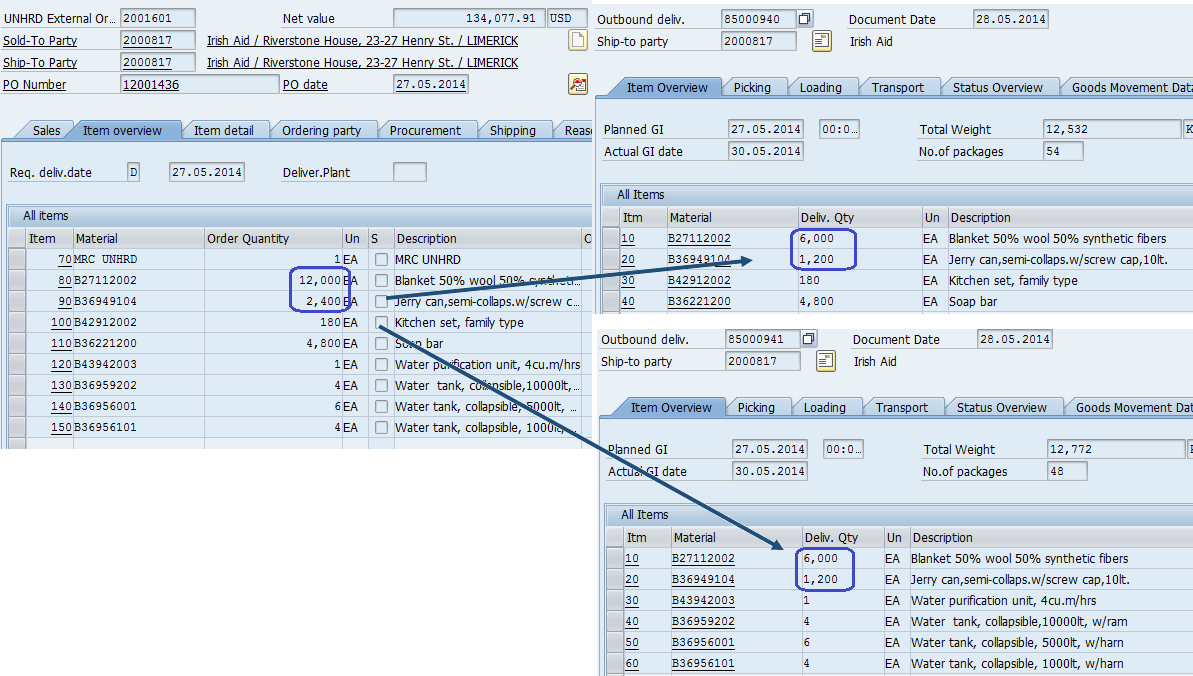

In case of partial shipments from same SO (e.g. multiple dispatches of wide cargo or due to partial availability of items) editing of different cargoes can be performed at the stage the Outbound Deliveries are created. Go to "Create Outbound Delivery" thru transaction VL01N to create first delivery from SO.

In case the same material has to be send out in more shipments, when creating the Outbound Delivery decrease the quantity of items to match with composition of first cargo to be shipped; remove totally the line items in case some materials are not be be included in the first shipment. The system will automatically decrease the required quantity for the forthcoming Outbound Delivery returning their balances into the SO:

In case the Partner asks for extra materials once the fist lot has left the warehouse, thereof the Good Issue has been posted against the Outbound Delivery, go to "Change Outbound Delivery" thru transaction VL02N, click on Outbound Delivery on the top menu, select Deliver Sales Order and pick the new material codes added on the SO on a later stage.

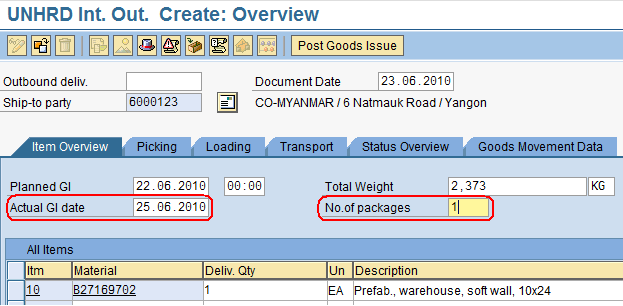

Fill in the Actual Goods Issue date and enter the Number of Packages (which is the total number of packages on the Packing List) in the Overview screen:

Go back ![]() , save

, save ![]() the Outbound Delivery:

the Outbound Delivery:

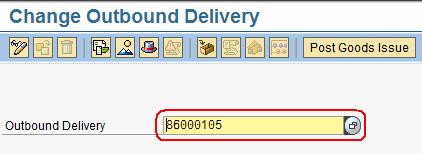

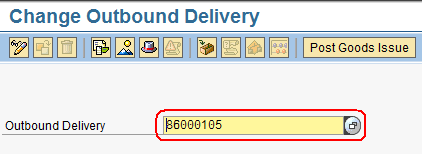

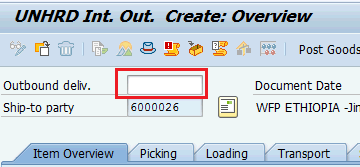

To complete the Outbound Delivery all the mandatory fields have to be entered; go to "Change Outbound Delivery" thru transaction VL02N, and enter the Outbound Delivery number:

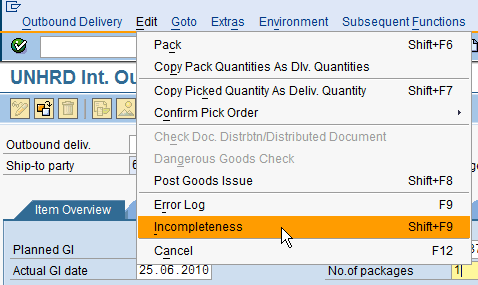

To edit all mandatory fields select:

Edit > Incompletion log

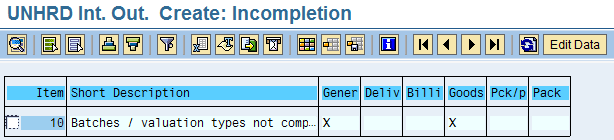

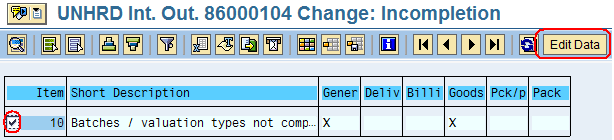

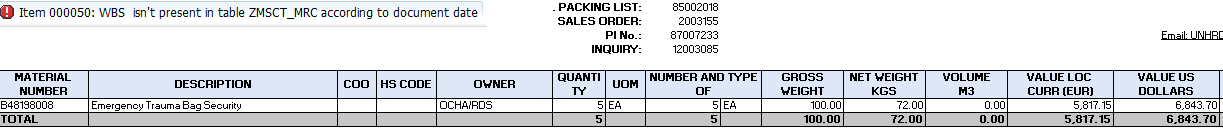

A message such as the following will appear:

| Update Sales Order Status to enable Delivery | |

| Performer: | Logistics |

| Role: | Logistics Assistant |

| Transaction : | WingsII – LX03 |

Select Batches to be associated to the Delivery

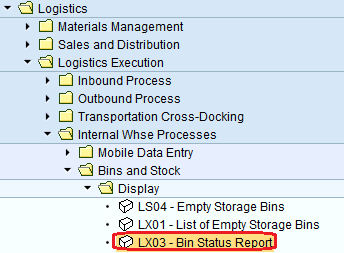

The Bin Status Report is used to identify and select the batches to be issued out from WMS. To access this report follow the patch below:

Logistics > Logistics Execution > Internal Whse Processes > Bins and Stock > Display

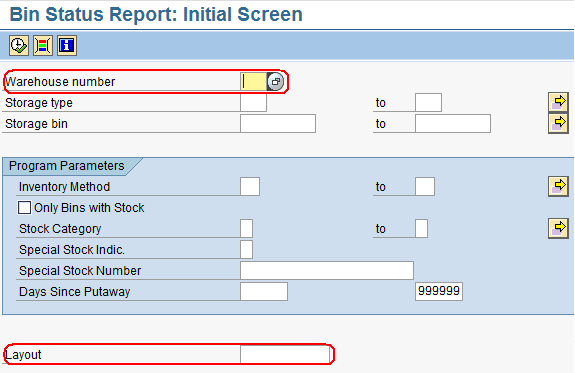

In the Initial Screen enter the fields ‘Warehouse Number’ and ‘Layout’ with proper information:

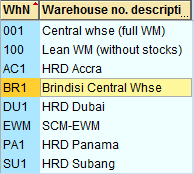

From the drop down menu choose the warehouse to be used for the Outbound Delivery:

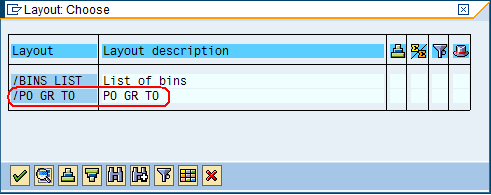

For the Layout choose ‘PO GR TO’:

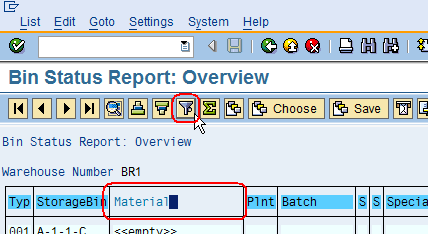

In the overview screen highlight the Material column and then click on the ‘Set Filter’ button ![]() :

:

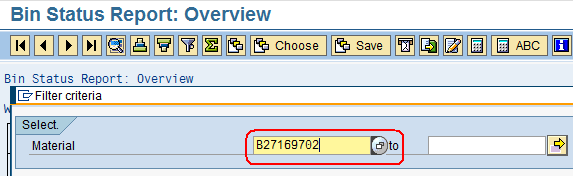

Enter the Material Code from the Sales Order to be checked and press ‘Enter’:

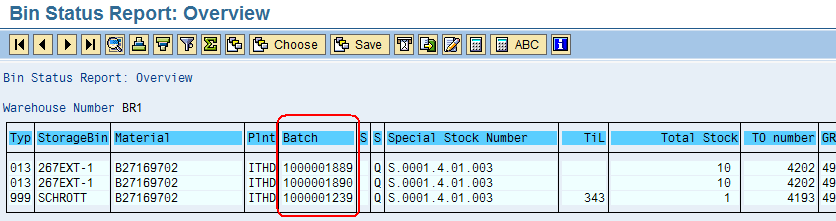

Filter also for the WBS element relevant for the stock owner to be utilised. Take note of the batch number(s) that best suit the quantity required (FIFO methodology has to be applied; please refer to your senior storekeeper and/or your Logistics Assistant/Officer regarding the bins to be selected):

| Complete Outbound Delivery | |

| Performer: | Logistics |

| Role: | Logistics Assistant |

| Transaction : | WingsII – VL02N |

Complete Outbound Delivery

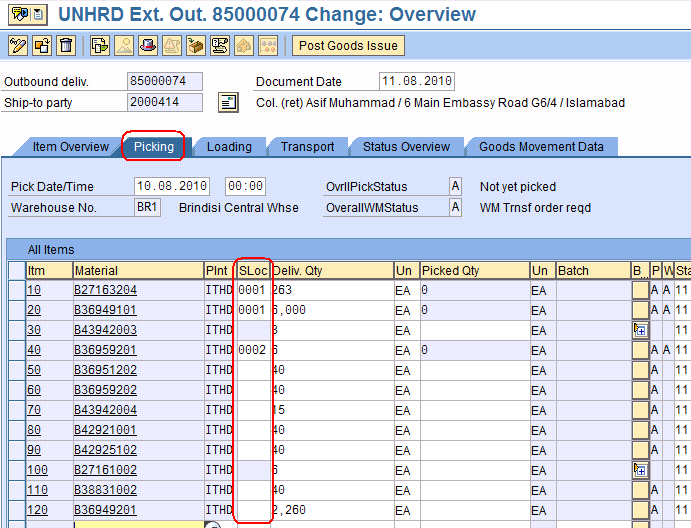

Open the Outbound Delivery document created before in order to update it with the batch information retrieved above:

Rerun the Incompleteness check:

Edit > Incompletion log

Select all line items and click on ![]() :

:

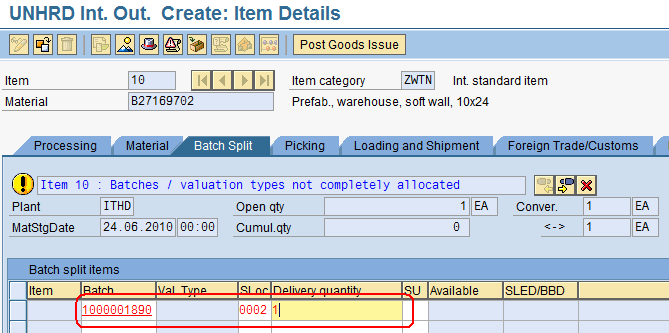

Enter the selected batch(es), the storage locations ‘0002’ and the quantity of each batch selected until the open quantity is fulfilled:

Click on ![]() to check if further information needs to be entered in the line item. The system should eventually return the following message:

to check if further information needs to be entered in the line item. The system should eventually return the following message:

Check and fill the Storage Location for all Line Items:

Click on ‘Next Incomplete Data’ field ![]() to edit the other line items that must be completed. Then click again on the ‘Next Incomplete Data’ field to return to the Delivery main page and click on

to edit the other line items that must be completed. Then click again on the ‘Next Incomplete Data’ field to return to the Delivery main page and click on ![]() to save it, taking note of the delivery number:

to save it, taking note of the delivery number:

NOTE the system does not allow the picking from the receiving area (Storage Type 902); in case the system does not process al materials in the TO, check if this is the reason why the remaining material – not picked - are not processed; go to transaction LB10 'Display Transfer Requirement: list for Storage Type' to complete the putaway process at receipt time.

Update Delivery with Shipment Information

| Update Delivery with Shipment Information | |

| Performer: | Logistics |

| Role: | Logistics Assistant |

| Transaction : | WingsII – VL02N |

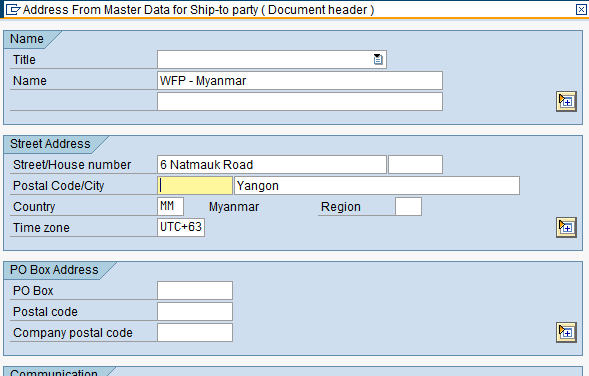

If the consignee details have not been inserted in the Ship-to-Party fields of the Sales Order, open the Outbound Delivery document created in order to update it with the Shipment Information:

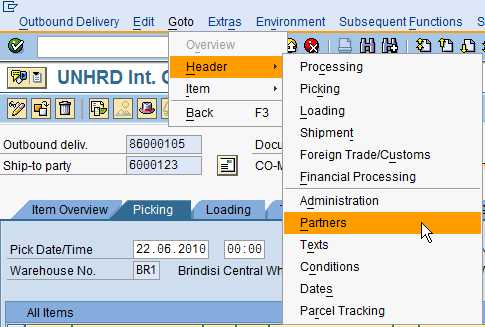

To edit the Shipment Information, use the following path:

Goto > Header > Partners

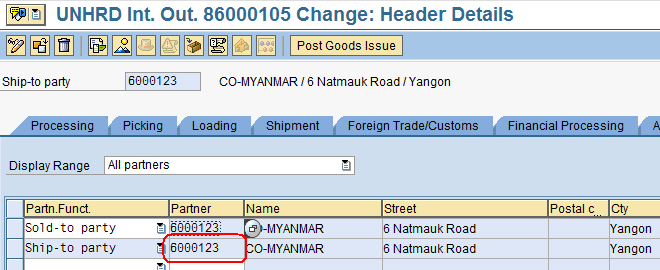

Double-click on the Partner Number in ‘Ship-To-Party’ line:

Enter all relevant consignee information:

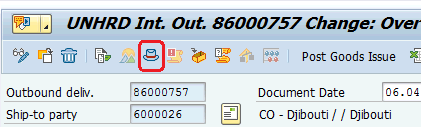

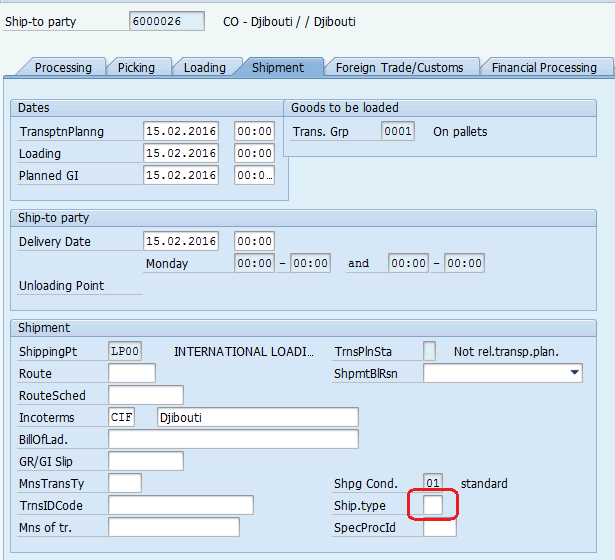

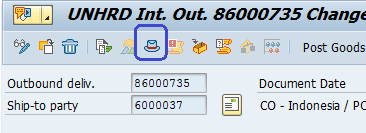

Complete the Outbound Delivery by entering eventually change the code to be associated to the means of transport that will be adopted for the shipment. Go to Change Outbound delivery (transaction VL02N) anc click on the OD header icon:

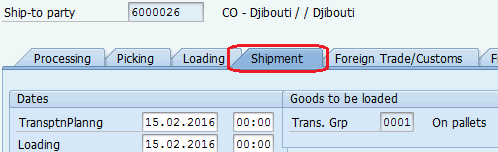

Click on the 'Shipment' Tab:

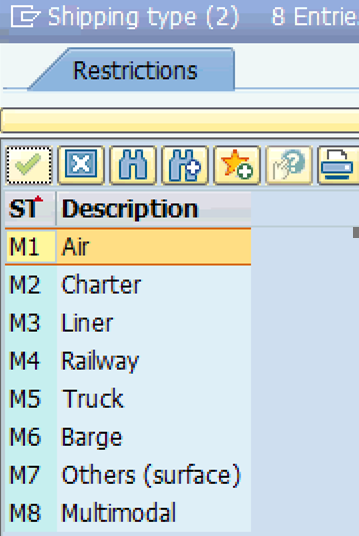

Click on the scroll down menu available on the 'Ship.type' field:

Select the code of the means of transport adopted to the shipment:

NOTE: The list of codes to be adopted for UNHRD Outbound Deliveries should be limited to those in the table below where explanations of their adoption is provided:

| Shipping type codes available in WINGS | Shipping type Descriptions available in WINGS | Explanation |

|---|---|---|

| M1 | Air | Air commercial -small cargo- shipments |

| M2 | Charter | Air charter - full chartered aircraft- shipments |

| M3 | Liner | Sea shipments |

| M5 | Truck | Land shipments |

| M7 | Others (surface) | Multimodal shipments |

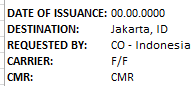

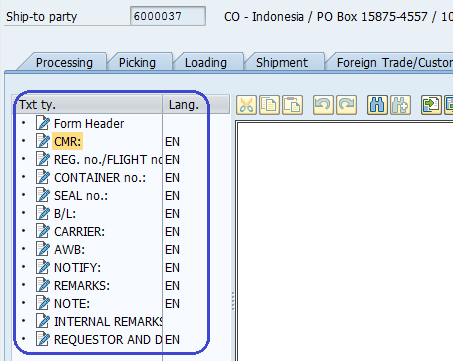

Enter also further information on the shipment, when and if available, such as name of Freight Forwarder performing the transport service -Carrier-, notes or remarks and about data grouped below by means of transport; the system carries over those information on the FINAL PACKING LIST output, part in the top-right side and part on the bottom-right side (e.g. notes and remarks)

1) CMR and Seal in case of road transport

2) B/L, Container n. and Seal in case of sea transport

3) AWB, Registration and Flight number in case of airlift

Also it is possible to enter notes for internal use only.

To enter this information go to the Outbound Delivery Header by clicking on the button circled in blue below:

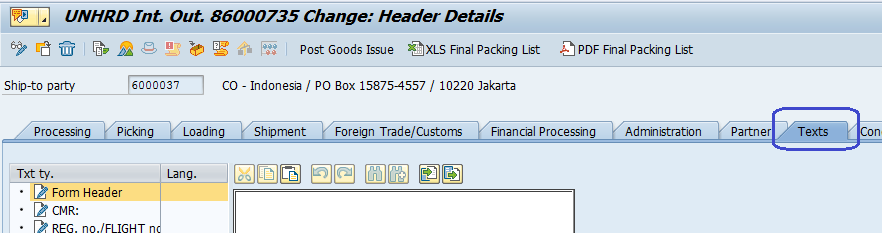

Go to the TEXT tab:

Edit the required fields, considering the combination of information grouped above by means of transport as the system excludes fields that are not compatible with ea other (e.g. don't fill in the Container n. if AWB is entered):

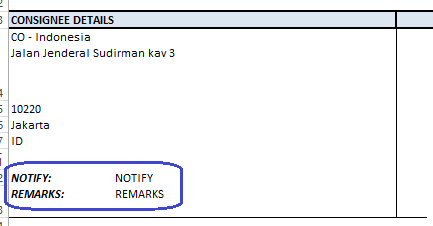

Notes and remarks are carried over on the FINAL PACKING LIST after the consignee details:

NOTE All above information can be amended until the GOOD ISSUE is posted.

Click on ![]() to save the Outbound Delivery document

to save the Outbound Delivery document

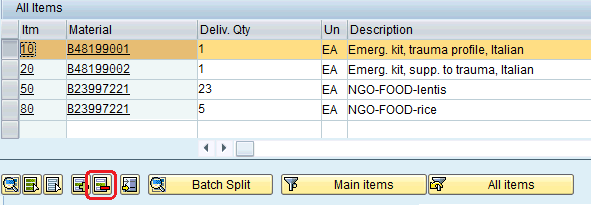

Delete Outbound Delivery

In case it is required, the Outbound Delivery can be emptied totally or partially and also deleted. To remove one line from the Outbound Delivery, go to transaction VL02N, select the line required to be deleted and click on the Delete Items(s)icon ![]() :

:

Repeat the action on all the items that requires to be removed and if all the Outbound is empty and it is required to delete it, click on the Delete icon ![]() before to save the OD.

before to save the OD.

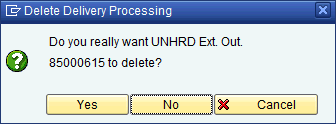

The System will prompt for the confirmation of this action:

Click on Yes and save the Outbound Delivery. The System will confirm the action taken by promptly the message below on the bottom of the screen:

NOTE: In some conditions it is required to empty the Outbound Delivery and keep the number generated by the system for future use - e.g. in case of nested issues within the Outbound Delivery -. In that cases follow above instructions and re-start the standard creation of the Outbound Delivery from the Sales Order making sure to paste the first Outbound Delivery number in the Outbound Deliv. field rather than allowing the system to generate a new number:

By saving the OD the system adopts the first OD n. generated against the SO.

Creation of outbound delivery for direct delivery process

When the sale to a partner regards all or some items that are meant to be delivered to final destination directly from suppliers’ location, the Direct Delivery procedure has to be applied.

It should be considered that even if it is no strictly required to issue Shipping documents such as UNHRD ‘Proforma Invoice/Packing List’ (e.g. in case of DAP as Incoterms), it is needed to generate the Outbound delivery in order to include such shipments in the operational reporting as any other consignment departing from UNHRD warehouses.

When creating a SO thru transaction VA01 – Sales Order Creation (ZHNO or ZHWO) or changing a SO thru transaction VA02 –Sales Order Change, add the material lines after the Service lines in order to generate the forthcoming Outbound Delivery. Follow the instructions on Order in case of Direct Delivery to complete this action.

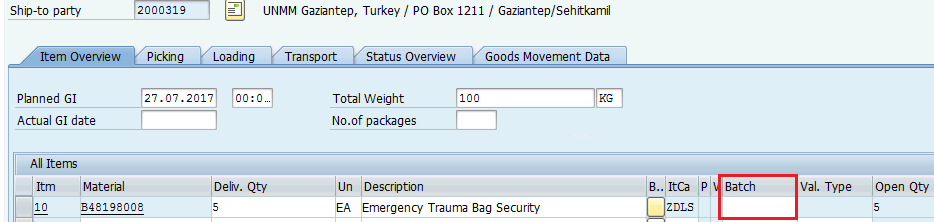

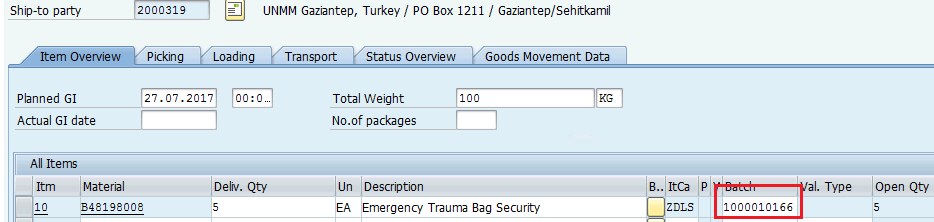

Once the SO is adapted to list material codes to be managed with Direct Delivery, go to VL01N Outbound Delivery Creation with ref. of the SO without forcing any other delivery type (e.g. ZS) because the item category ZDLS is automatically transferred from the SO to the Outbound Delivery.

If the material is batch managed, enter a batch number at line level:

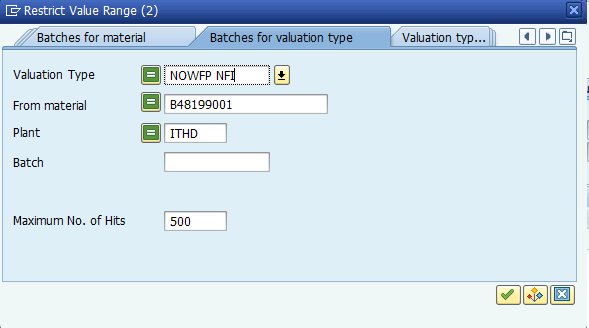

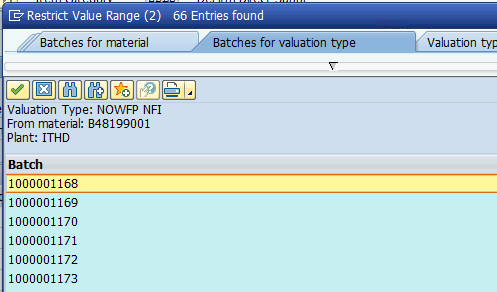

Search for a batch number by clicking on the drop-down menu. Enter the Valuation Type that applies to the type of material (e.g. WFP NFI, NOWFP NFI, etc.):

Click on any batch number valid for the material processed as this kind of delivery does not take effect on batches in the warehouse; click on ![]() to select the batch:

to select the batch:

NOTE: select the most recent batch in case of perishable items so that it won't expires in less than 365 days from its selection:

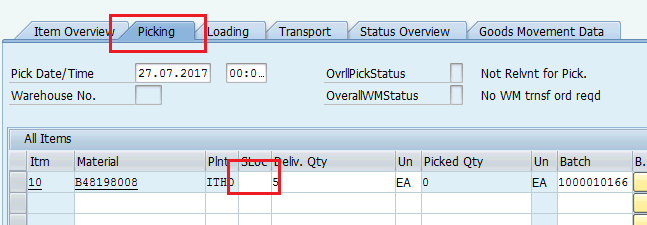

Enter Storage Location '0002' in the Picking tab:

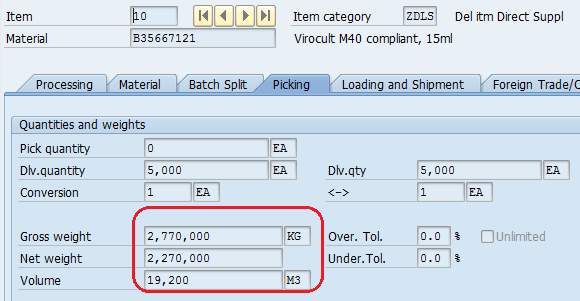

In case the material required to be shipped from supplier's location does not exist in make sure to change the item description (this should be done already at the SO level) and, more important, change the weights and volume in the Outbound Delivery in order to adapt it to the real cargo composition. In that case, the weights and volumes can be changed in the Picking tab at line level of the Outbound Delivery:

No storage location and picking process is required because the item category is ZDLS and it does not affect the warehouse activities.

NOTE: the Condition Type of the items shipped thru Direct Delivery process entered at SO level is derived by the Final Packing List to reflect the value in USD and local currency of items dispatched together:

After maintaining the batches for each item, and when cargo leaves the HRD premises, post the Goods Issue.

The Good Issue number in the Outbound Deliveries follows the 013* range.

When items are received at final destination, post the Proof of Delivery as per Chapter 6.5 Maintain Proof of Delivery

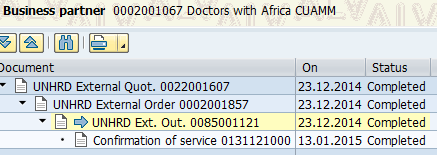

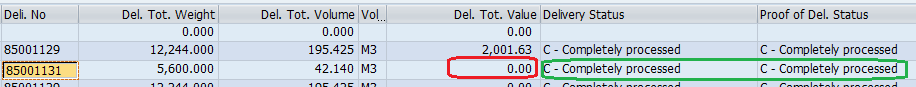

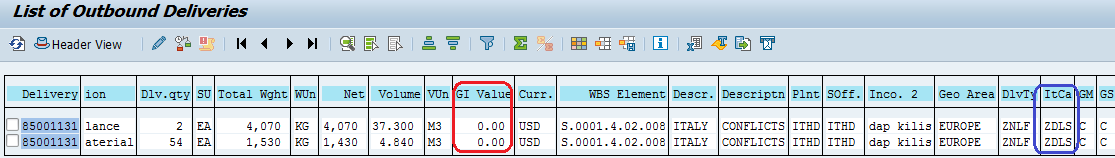

NOTE: The Outbound Delivery generated from a Direct Delivery process is visible on the various WINGS reports, such as the Logistics Reconciliation Report as any other delivery, with the only difference that the GI value is not reported, because there is no warehouse movement behind the good issue:

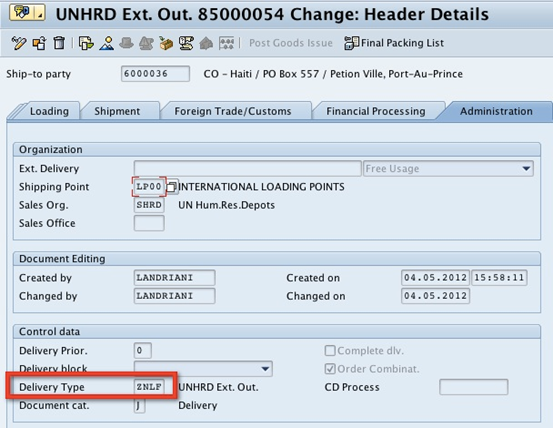

The outbound delivery type is derived from the SO type (e.g. ZNLF for External Outbound Delivery and ZWLF for Internal Outbound Delivery):

To define which Outbound Deliveries have been generated with Direct Delivery method, other WINGS monitoring reports such us the Activity Report POD Monitor show the Item category adopted in the SO and data can be filtered from there: