10.3 NFI Receipt: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

== Post Good Receipt against PO for NFI and POWM == | == Post Good Receipt against PO for NFI and POWM == | ||

== Post Good Receipt for items to be received under WHITE STOCK balances == | |||

Upon release of PONFs (and eventual POWMs for External Partners) which contains items available under the WHITE STOCK balances, the storekeepers have to issue the GR and produce the IR (even if the availability of WHITE STOCK covers only a portion of the total quantity procured – as in this case -). As usual, Procurement and Finance have to be informed that the GR has been issued, and signed Inspection Report have to be submitted to them and archived in the LOGISTICS files as well. | |||

When GR is posted, the Logistics officer or the storekeeper inform the SAN (Support Across the Network) unit asking for the decrease of WHITE STOCK balances accordingly with the quantity posted in the GR. To be noted that in case of procurement for external Partners, SAN unit decrease the stock only when the GR against the related POWM will be posted (meaning items will be received in WMS). | |||

The stock decrease is totally not-linked to the GR posted, meaning that it is crucial to communicate to SAN unit that the GR has been posted; | |||

When the reductions of WS figures are posted, SAN unit informs Procurement as unit responsible of the management of WS. | |||

In case of procurement from WHITE STOCK the following steps applies: | |||

Physically: | |||

• in case storage by ownership is applied, move the items from WHITE STOCK’s bins to Owner’s bins (meaning the Partner mentioned as WBS element in the Account Assignment tab of the PONF/POWM). | |||

• In case optimization of storage space is applied (items are stored based on material category rather than by Ownership), no physical transfer is required but just re-labeling of the units to show that they are not part of WHITE STOCK anymore but property of the Owner specified in the Account Assignment tab of the PONF/POWM (in case barcoding is adopted, the label will be produced by the system automatically as consequence of the step below | |||

• In case Customs references is applied, this information does not have to be changed as the Customs status of the items does have to comply with | |||

System-wise: | |||

• Create the Transfer Order that is generated after the above GR posting to complete the putaway from the ‘receiving area’ (standard incoming procedure) even if in reality the items are moved from the WS area. | |||

== Edit and Print Inspection Report == | == Edit and Print Inspection Report == | ||

| Line 85: | Line 101: | ||

Select the directory from the browse icon and chen click on Desktop and on Computer to save the INspection Report on the preferred location on the server or local disk. | Select the directory from the browse icon and chen click on Desktop and on Computer to save the INspection Report on the preferred location on the server or local disk. | ||

== | == Notify receipt of items to UNHRD sections and Partners == | ||

Revision as of 10:52, 3 November 2015

Post Good Receipt against PO for NFI and POWM

Post Good Receipt for items to be received under WHITE STOCK balances

Upon release of PONFs (and eventual POWMs for External Partners) which contains items available under the WHITE STOCK balances, the storekeepers have to issue the GR and produce the IR (even if the availability of WHITE STOCK covers only a portion of the total quantity procured – as in this case -). As usual, Procurement and Finance have to be informed that the GR has been issued, and signed Inspection Report have to be submitted to them and archived in the LOGISTICS files as well. When GR is posted, the Logistics officer or the storekeeper inform the SAN (Support Across the Network) unit asking for the decrease of WHITE STOCK balances accordingly with the quantity posted in the GR. To be noted that in case of procurement for external Partners, SAN unit decrease the stock only when the GR against the related POWM will be posted (meaning items will be received in WMS). The stock decrease is totally not-linked to the GR posted, meaning that it is crucial to communicate to SAN unit that the GR has been posted; When the reductions of WS figures are posted, SAN unit informs Procurement as unit responsible of the management of WS.

In case of procurement from WHITE STOCK the following steps applies: Physically: • in case storage by ownership is applied, move the items from WHITE STOCK’s bins to Owner’s bins (meaning the Partner mentioned as WBS element in the Account Assignment tab of the PONF/POWM). • In case optimization of storage space is applied (items are stored based on material category rather than by Ownership), no physical transfer is required but just re-labeling of the units to show that they are not part of WHITE STOCK anymore but property of the Owner specified in the Account Assignment tab of the PONF/POWM (in case barcoding is adopted, the label will be produced by the system automatically as consequence of the step below • In case Customs references is applied, this information does not have to be changed as the Customs status of the items does have to comply with System-wise: • Create the Transfer Order that is generated after the above GR posting to complete the putaway from the ‘receiving area’ (standard incoming procedure) even if in reality the items are moved from the WS area.

Edit and Print Inspection Report

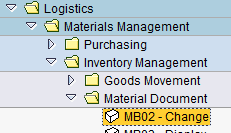

Go to transaction MB02 or follow the patch below:

Logistics > Materials Management > Inventory Management > Material Document > MB02 – Change

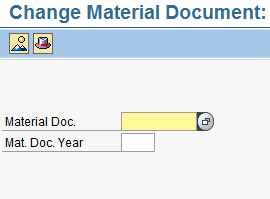

Enter the Material Document and hit ![]() :

:

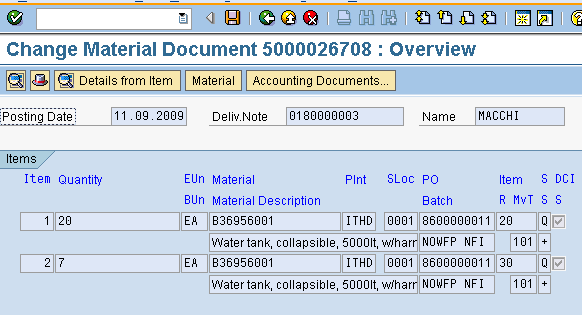

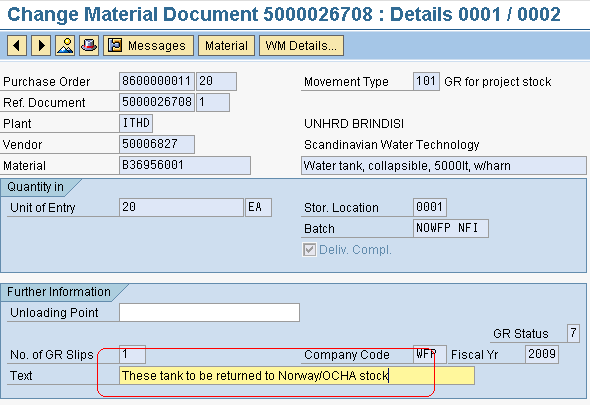

The system displays the details of the GR posted:

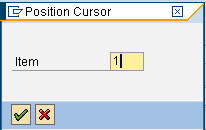

Click on ![]() and type in the line item number:

and type in the line item number:

In the Text field type any required remarks:

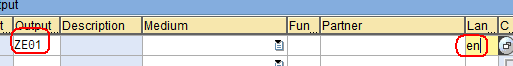

Click on ![]() Enter ZE01 as Output and EN as language:

Enter ZE01 as Output and EN as language:

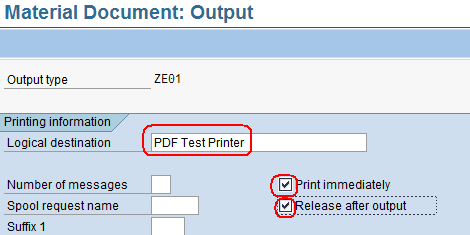

Click on ![]() and enter “PDF Test Printer” as logical destination and match the 2 options circled below and hit

and enter “PDF Test Printer” as logical destination and match the 2 options circled below and hit ![]() and on

and on ![]() to return to previos screen:

to return to previos screen:

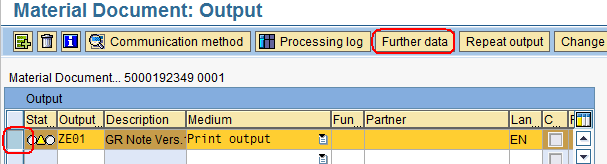

Select the line Output created and click on ![]() :

:

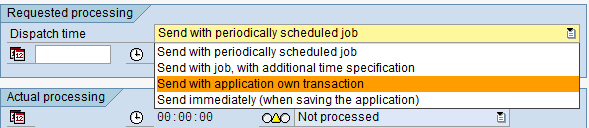

Select “Send with application own transaction” as Requested processing:

Hit ![]() and on

and on ![]() to return to previous screen and click on

to return to previous screen and click on ![]() twice.

twice.

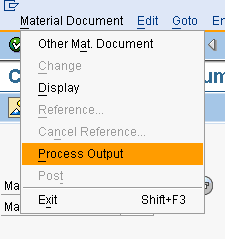

Click on “Material Document” and on Process Output:

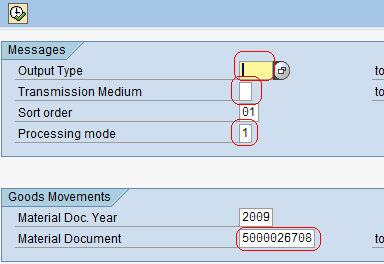

The system will prompt the Document number automatically; enter ZE01 in the Output Type field and 1 in the Processing Mode field and hit on ![]() :

:

NOTE In case it is requried to reprint or resave and Inspection Report already processed, entre 3 as Processing Mode.

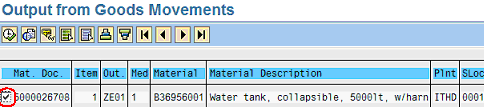

Select the material document and hit on ![]() :

:

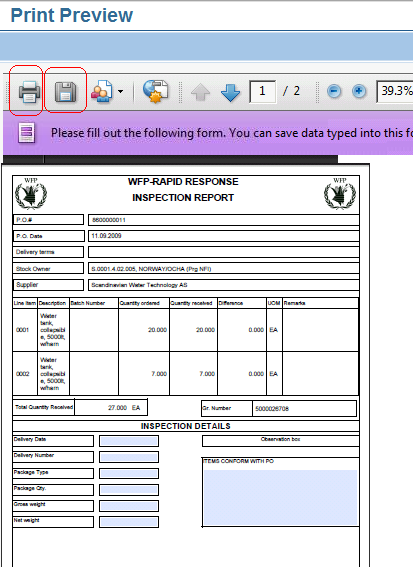

The system will return the Inspection Report form that can ebe ither saved on the computer as Adobe file or printed out on local printer after the required information have been entered:

Fill in the cells by entering the informtaion required to complete the printout in the editable fields (in gray) such as the delivery date, the packaging details, the weight of cargo received, observation on the materials, if any, name of who inspected the materials and date of inspection.

Hit on ![]() to save the report and select the preferred location on local computer:

to save the report and select the preferred location on local computer:

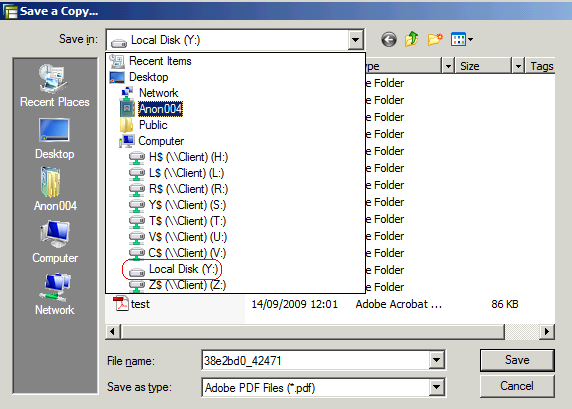

Browse for the desired location, change file name if required and hit on ![]()

NOTE The C: drive of your computer is listed as 'Local Disk Y:'. Don't save the Inspections Reports on the 'Desktop' ad the one shown it is related to Citrix Server, not the desktop on user's computer.

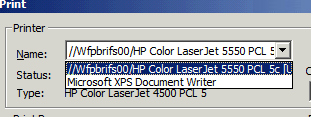

To print the Inspection Report click on ![]() . The system shows the default printer set on the local computer; anyother printer installed on it can be selected from the drop-down menu:

. The system shows the default printer set on the local computer; anyother printer installed on it can be selected from the drop-down menu:

Select a local printer and hit on OK.

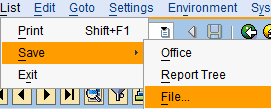

To save the Inspection Report click on List on the menu bar on the top, then on Save and File:

Select the preferred format (“Spreadsheet” is recommended) and hit ![]() .

Select the directory from the browse icon and chen click on Desktop and on Computer to save the INspection Report on the preferred location on the server or local disk.

.

Select the directory from the browse icon and chen click on Desktop and on Computer to save the INspection Report on the preferred location on the server or local disk.